Anaplan for Production Planning

Outpredict. Outplan. Outperform.

With Anaplan CoPlanner for Demand Planning.

Why Anaplan Production Planning software?

Enable planning agility

Quickly determine how to allocate employees, materials, and production capacity through a multi-dimensional, attribute-based planning process.

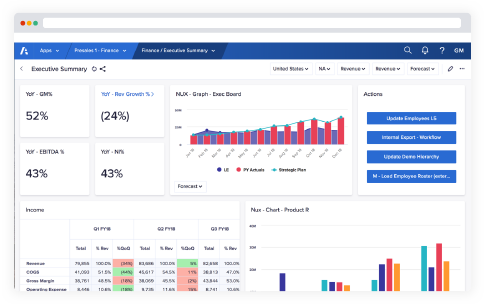

Plan dynamically

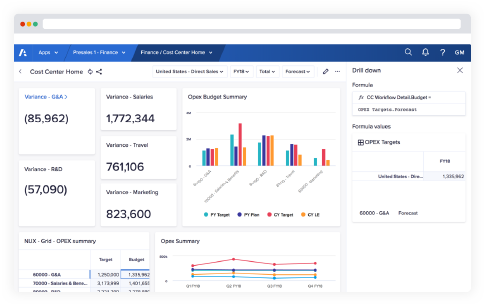

Plan in a dynamic, continuous way by measuring, monitoring, drilling deep into root causes, performing “what-if” analysis and making production plan changes in real-time.

Empower Connected Planning

Collaborate with suppliers, manufacturers, and trading partners to align plans for maximum efficiency.

Drive budget compliance

Enable the conversion of volumes to value, ensuring compliance with financial budgets.

Key challenges and how Anaplan solves them

Common Challenges

Poor adoption of planning systems

Anaplan Capabilities

Create personalized views for planning at aggregate and detailed levels

Lack of integration between production and sales

Drive flexible business logic to convert attribute-based plans into SKU configurations

Loss of flexibility due to an extended frozen horizon for planning

Enable instant allocations via transparent and consistent models for both actuals and forecast