Learn why connected enterprises drive higher shareholder returns

Anaplan for Product and Customer Profitability

Why Anaplan Inventory Planning software?

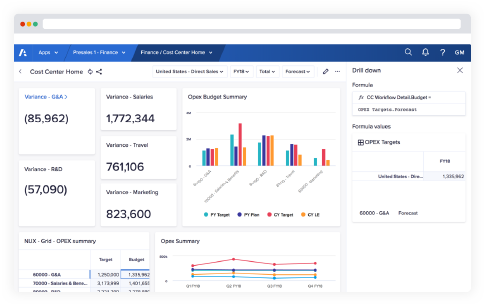

Model cost drivers

Model cost drivers from finance through to the supply chain in order to understand impacts from raw materials, configuration changes, labour inflation, OEI, FX, etc.

Increase allocation transparency and speed

Increase transparency and speed of allocations, including absorption of overheads on a consistent basis–both historically and in the future.

Connect planning across the enterprise

Collaborate with all departments across the enterprise to align objectives with operational tactics and financial plans.

Key challenges and how Anaplan solves them

Common Challenges

Lack of ability to understand the volume, price, mix, FX, and brand investment to optimize organic growth

Lack of visibility into how changing costs in the supply chain impact profitability in consumer markets

Minimal ability to align brand and customer targets to operational resources and personnel

Lack of standard process and visibility to drivers and allocations that disconnects business users from the levers of change

Anaplan Capabilities

Provide analytical tools to isolate the impacts of volume, price, mix, FX, and brand ROI between any combination of products, time, and versions

Track the causes of cost changes to brands and markets by tracking key drivers –from raw materials through complex production processes and distribution

Provide top down and bottom up planning capabilities by brand and customer to right-size resourcing and investment decisions

Enable instant allocations via transparent and consistent models for both actuals and forecast